What is the Purpose of Minimum Flow?

Randal FermanOver the years use of the term “minimum flow” has evolved. Decades ago industrial centrifugal pump manufacturers quoted a single, relatively low value for minimum flow intended to prevent users from running their pumps to destruction. The term “minimum flow” generally meant the lowest continuous flow the pump was permitted to operate, without reference to duration, vibration level or other criteria. Today we have minimum flow values for continuous operation, for intermittent operation and for permissible temperature rise.

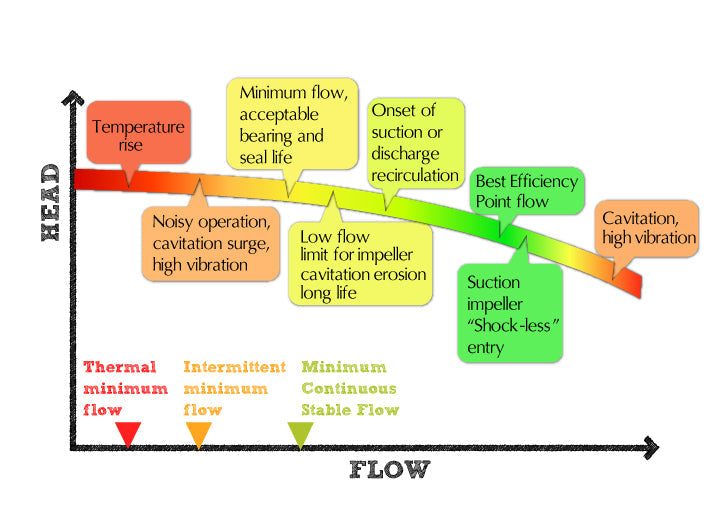

The accompanying chart Pump phenomena and minimum flows shows the relationships among the various off-design pump phenomena and minimum flow conditions. The head versus rate of flow curve with indicated phenomena is a variation of S. Gopalakrishnan’s from his well-cited paper titled, “A New Method for Computing Minimum Flow,” Proceedings of the Fifth International Pump Users Symposium; Texas A&M University, May 1988, pp. 41-47. As an aside, I recall Gopal (everyone knew him by that name) had made a local technical presentation using the now well-known chart, before it was published. Evidently the chart was copied from a handout of the overhead slides and was quickly pirated by another, and then others. Copies or variants of this chart are now found widely in papers and presentations on pumps.

The quoted minimum flow for continuous operation is usually called “Minimum Continuous Stable Flow” or its more common abbreviation “MCSF.” It is the flow below which the pump should not be operated continuously. The usual purpose of MCSF is to achieve satisfactory bearing and seal life; however MCSF may be based on other considerations. Any of the following factors may be considered in establishing the MCSF:

- manufacturer’s experience

- rule of thumb

- calculated onset of suction recirculation or discharge recirculation

- radial thrust

- temperature rise

- cavitation erosion intensity

- maximum permissible pressure rise (for system purposes)

- maximum permissible power rise (high specific speed and axial flow pumps)

- a combination of the above factors or others not listed

For hydrocarbon process industry API 610 specification pumps, the value of MCSF is normally coincident with the lower flow limit of the “Acceptable Operating Range” (refer to chart titled “Vibration limits for Allowable Operating Range and Preferred Operating Range”) where a specified vibration limit is not to be exceeded.

MCSF is a value that can range from roughly 10% to 80% of Best Efficiency Point flow depending on pump size and type, operating speed, impeller suction geometry, liquid density, and other factors. A size 2” (50mm) discharge single-stage process pump may have an MCSF as low as 10% of BEP flow. MCSF is often in the range of 30% to 60% of BEP flow for process pumps with discharge sizes 3” (75 mm) and larger. Large mixed flow vertical pumps and very high head-per-stage centrifugal pumps may have an MCSF greater than 60% of BEP flow. Axial flow pumps have a power curve that rises toward shutoff and minimum flow may be limited by the power rating of its driver.

On certain high energy pumps the minimum flow is governed by cavitation erosion damage. Minimum continuous flow for 40,000-hour impeller erosion life is where the system NPSH Available curve intersects the pump’s NPSH Required curve, at lower-than-BEP flow.

Intermittent minimum flow, when specified, is usually given as a percentage of MCSF. On some applications the governing value may be based on temperature rise. On large high energy pumps the value of intermittent minimum flow could be, for example, “70% of MCSF and not to exceed 100 hours per year.”

For some applications a thermal minimum flow or “Minimum Continuous Thermal Flow” is specified based on permissible liquid temperature rise. MCTF is usually, but not necessarily, lower than MCSF. While a pump thermal minimum flow is not always specified, the end user can readily calculate its value based on input mechanical power heating up the liquid. The limiting temperature rise is based on a safe margin to prevent flashing of the pumped liquid to vapor, potentially causing pump seizure.

Thermal minimum flow is not normally a concern at pump start-up as long as the closed discharge valve is set to begin opening right away. If the margin of system NPSHA above pump NPSHR is minimal, then the temperature rise conditions at pump start-up should be checked carefully.

A few pump applications, such as a vertical turbine jockey pump for maintaining pressure in a large fire sprinkler system, can potentially operate continuously at shutoff while pump suction recirculation mixes with the water in the sump in which it operates. The sump acts as a heat sink and a minimal water temperature rise is not a problem. This example is a rare exception to an almost invariable stricture on operating the pump continuously at shutoff.

The purpose of minimum flow is generally to prevent undue wear and tear or damage to the pump. In the real environment of a process or utility plant, a pump is operated at just about any condition demanded by the situation at hand. Thus there are different pump minimum flows for different purposes.

For an independent evaluation of a pump minimum flow issue, contact an experienced consulting engineer who can help with your specific application. Please take a look at our services to see our areas of expertise.

52 comments

Does the minimum flow vary with type of pump(centrifugal, reciprocating, diaphragm,gear,screw etc),impeller (axial/radial/mixed flow etc) etc?. Give a link to study/download. If we design a pump whose flow can be adjusted (by varying stroke of pump)can we solve this problem?.

Dear Rajib Mukhopadhyay,

The minimum flow operation proposed is quite low, as you are obviously aware. Temperature rise is a concern. The pump manufacturer should take a look at this to ensure that the temperature rise does not lead to internal flashing (vaporization). This would include checking flows and temperature rise through the pump’s internal recirculation passages such as wear rings and bushings.

Also, vibration at such low flows will likely exceed API 610 specifications. This may or may not be acceptable and should be discussed with the pump manufacturer. It’s possible, for instance, the manufacturer might suggest a lower speed selection or a stiffer rotor design, to name two possible alternatives.

Concerning the shell and tube heat exchanger, these can be readily customized for the application and there should be no problem selecting the tube side configuration to satisfy the flow resistance requirements.

The proposed conditions, as generally described, are feasible, but the technical details of the pump and the heat exchanger selections are important.

Best regards,

Randal

We want to unload a oil well at offshore and send the flow through the Crude oil export pump to other platform. The pump will take suction from a production separator and first feeds a booster pump and then the Crude oil export pump.

Initially the Oil well production will be much much below the rated flow of the COEP. So the plan is to run the COEP on recycle. But as the oil is bound to get heated up beyond pump design temperature, designer has proposed to install heat exchanger of the recycle line and cool the oil that goes back to the suction vessel , production separator.

My query is can the pump system survive if the initial well flow is very low (about 5000 bopd) as against 75000 bopd in normal condition.

Can the min flow recirculation line of such pump have a shell and tube heat exchanger, in which the recycle oil flow passes through the tube side. Can the recycle stream handle such resistances of passing through the tube side of the exchanger and still satisfy min flow requirements adequately?

Please comment on the feasibility, pros-cons of the above proposal.

Dear,

I’m a piper and involved in a system check on a pipeline with two parallel distribution multistage(12) horz. pumps (Flowserve). (one running.). These are running with a VFD.

Normal 180 M3/hr@dynamic head of 1400m. I ‘m still searching for the setting of the Automatic Recirculation Control Valve. Still searching for this datasheet of this valve :(

When the demand in the discharge is less the minimum flow will return to directly to the storage sphere with locked open valves. This will be a new line from this minimum flow valve. The minimum flow is 70M3/hr—>1620m Head. Taken from the pumpcurve equals to 82.5 bar. At deadhead cond. (zero flow) a max. head of 1680 m. This give a max diff. pressure of 85.5 Bar. (Spec. Gravity 0,519) The max pressure in the suction is the max outlet pressure of the sphere. at the bottom. This spere is forseen with a safety stting of 15 Barg. the max. height spere is 18.6m equals 0.91 Bar. The max. suction pressure will be 15.91 Bar. Adding this to the max. operating press. gives 98.4 Barg but adding this to the deadhead pressure of the pump this will give a maximum discharge of 15.91+85.5=101.4 Bar. So the design pressure taken for the minimum flowline is 101.5 Bar @ 50 degC. the max temp that can be reached is corrs. to the max vapour press. in the sphere safety valve @15Bar=38.5degC. The quantity taken out is pumped back to the sphere at the time of no demand to the pipeline. The variable frequency drive will lower the speed at that time but the pump will still running. I don’t think that I need more information of this minimum flow valve since the design of this line is 101.5 Bar @ 50 degC.

Please any comment?

Thank you in advance. Freddy

Matt,

The risk is remote, but there are extreme scenarios where the LP discharge header could become over-pressurized by the HP pumps. Imagine, for instance, that LP and the HP discharge valves are closed, or are nearly closed. Now, if one or more HP pumps are operating or are turned on, then one or more of the HP bypass minimum flow valves open up and the LP discharge header becomes over-pressurized. If one wants to reduce the risk of over-pressurization, then one should consider the possibilities by virtue of the connected piping and unplanned operating events. It’s a sort of ‘What’s the worst that can happen?’ way of thinking but this point of view might ultimately save lives.

Thank you for this one.

Randal