What is the Purpose of Minimum Flow?

Randal FermanOver the years use of the term “minimum flow” has evolved. Decades ago industrial centrifugal pump manufacturers quoted a single, relatively low value for minimum flow intended to prevent users from running their pumps to destruction. The term “minimum flow” generally meant the lowest continuous flow the pump was permitted to operate, without reference to duration, vibration level or other criteria. Today we have minimum flow values for continuous operation, for intermittent operation and for permissible temperature rise.

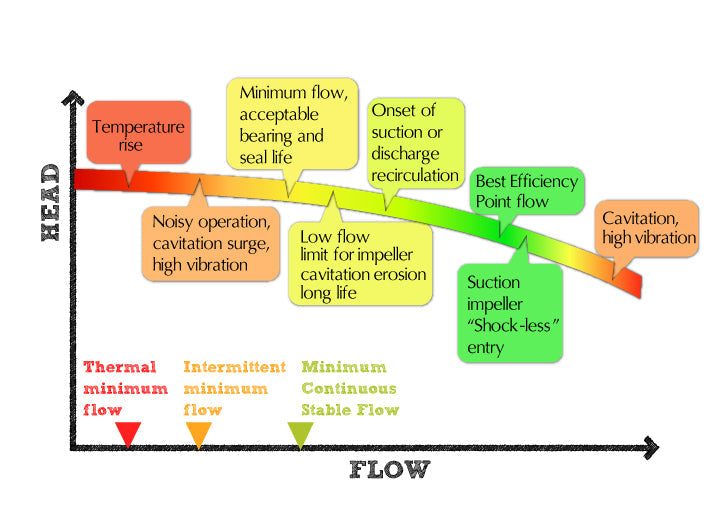

The accompanying chart Pump phenomena and minimum flows shows the relationships among the various off-design pump phenomena and minimum flow conditions. The head versus rate of flow curve with indicated phenomena is a variation of S. Gopalakrishnan’s from his well-cited paper titled, “A New Method for Computing Minimum Flow,” Proceedings of the Fifth International Pump Users Symposium; Texas A&M University, May 1988, pp. 41-47. As an aside, I recall Gopal (everyone knew him by that name) had made a local technical presentation using the now well-known chart, before it was published. Evidently the chart was copied from a handout of the overhead slides and was quickly pirated by another, and then others. Copies or variants of this chart are now found widely in papers and presentations on pumps.

The quoted minimum flow for continuous operation is usually called “Minimum Continuous Stable Flow” or its more common abbreviation “MCSF.” It is the flow below which the pump should not be operated continuously. The usual purpose of MCSF is to achieve satisfactory bearing and seal life; however MCSF may be based on other considerations. Any of the following factors may be considered in establishing the MCSF:

- manufacturer’s experience

- rule of thumb

- calculated onset of suction recirculation or discharge recirculation

- radial thrust

- temperature rise

- cavitation erosion intensity

- maximum permissible pressure rise (for system purposes)

- maximum permissible power rise (high specific speed and axial flow pumps)

- a combination of the above factors or others not listed

For hydrocarbon process industry API 610 specification pumps, the value of MCSF is normally coincident with the lower flow limit of the “Acceptable Operating Range” (refer to chart titled “Vibration limits for Allowable Operating Range and Preferred Operating Range”) where a specified vibration limit is not to be exceeded.

MCSF is a value that can range from roughly 10% to 80% of Best Efficiency Point flow depending on pump size and type, operating speed, impeller suction geometry, liquid density, and other factors. A size 2” (50mm) discharge single-stage process pump may have an MCSF as low as 10% of BEP flow. MCSF is often in the range of 30% to 60% of BEP flow for process pumps with discharge sizes 3” (75 mm) and larger. Large mixed flow vertical pumps and very high head-per-stage centrifugal pumps may have an MCSF greater than 60% of BEP flow. Axial flow pumps have a power curve that rises toward shutoff and minimum flow may be limited by the power rating of its driver.

On certain high energy pumps the minimum flow is governed by cavitation erosion damage. Minimum continuous flow for 40,000-hour impeller erosion life is where the system NPSH Available curve intersects the pump’s NPSH Required curve, at lower-than-BEP flow.

Intermittent minimum flow, when specified, is usually given as a percentage of MCSF. On some applications the governing value may be based on temperature rise. On large high energy pumps the value of intermittent minimum flow could be, for example, “70% of MCSF and not to exceed 100 hours per year.”

For some applications a thermal minimum flow or “Minimum Continuous Thermal Flow” is specified based on permissible liquid temperature rise. MCTF is usually, but not necessarily, lower than MCSF. While a pump thermal minimum flow is not always specified, the end user can readily calculate its value based on input mechanical power heating up the liquid. The limiting temperature rise is based on a safe margin to prevent flashing of the pumped liquid to vapor, potentially causing pump seizure.

Thermal minimum flow is not normally a concern at pump start-up as long as the closed discharge valve is set to begin opening right away. If the margin of system NPSHA above pump NPSHR is minimal, then the temperature rise conditions at pump start-up should be checked carefully.

A few pump applications, such as a vertical turbine jockey pump for maintaining pressure in a large fire sprinkler system, can potentially operate continuously at shutoff while pump suction recirculation mixes with the water in the sump in which it operates. The sump acts as a heat sink and a minimal water temperature rise is not a problem. This example is a rare exception to an almost invariable stricture on operating the pump continuously at shutoff.

The purpose of minimum flow is generally to prevent undue wear and tear or damage to the pump. In the real environment of a process or utility plant, a pump is operated at just about any condition demanded by the situation at hand. Thus there are different pump minimum flows for different purposes.

For an independent evaluation of a pump minimum flow issue, contact an experienced consulting engineer who can help with your specific application. Please take a look at our services to see our areas of expertise.

52 comments

Many thanks Randal

Aurel,

I will take liberty to rephrase this as a question: “How is pump minimum flow affected by a reduction in speed?”

Generally it would be safe to reduce pump minimum flow proportional to the reduction in pump speed. That is, if the minimum flow value provided by the manufacturer is based on methods that take into account the onset of suction recirculation, NPSH margin ratio, and energy level of the pump.

However, the NPSH-Required and energy levels vary exponentially with speed, so that at lower speeds one should be able to run a pump a lower minimum flows than would be indicated by a simple linear extrapolation.

Thank you for bringing up this excellent point.

Randal

Hi dear Gents

And congrats for this discussion. Please, assume on rated speed we have a clear minimum continuous flow defined by pump vendor, how that minimum flow is changes if the pump speed is changes to by using a VDF?

The lower the pump speed, the lower the minimum continuous flow too?

Many thanks for your feedback

Knidly tell me the conditions of Minimum flow of centrifugal pumps?

Jaqueline,

Minimum Continuous Thermal Flow (MCTF) can be an issue with high head multi-stage pumps. Liquid heats up as it passes through the pump. Some of this heated liquid passes through the axial thrust balance device and returns to suction. If sufficiently heated, this liquid may now flash suddenly into vapor and cause catastrophic failure of the pump. This is particularly a concern, and definitely an operational constraint, with boiler feed water applications where the pump takes suction directly from an elevated deaerator tank. In such an arrangement, the margin of NPSH Available at the pump suction, above the NPSH Required by the pump, is limited by the height of the deaerator and resistance losses in the piping.

For the majority of pump applications the calculated MCTF will be substantially lower than the Minimum Continuous Stable Flow (MCSF).

Best holiday wishes,

Randal