Centrifugal pumps and compressors are both rotating equipment devices. Each is a machine that imparts kinetic energy to the fluid to create pressure and move liquids, gases, and other process materials. So what are the differences between pumps and compressors? The main differences are intimately connected with the properties of the process fluid medium being […]

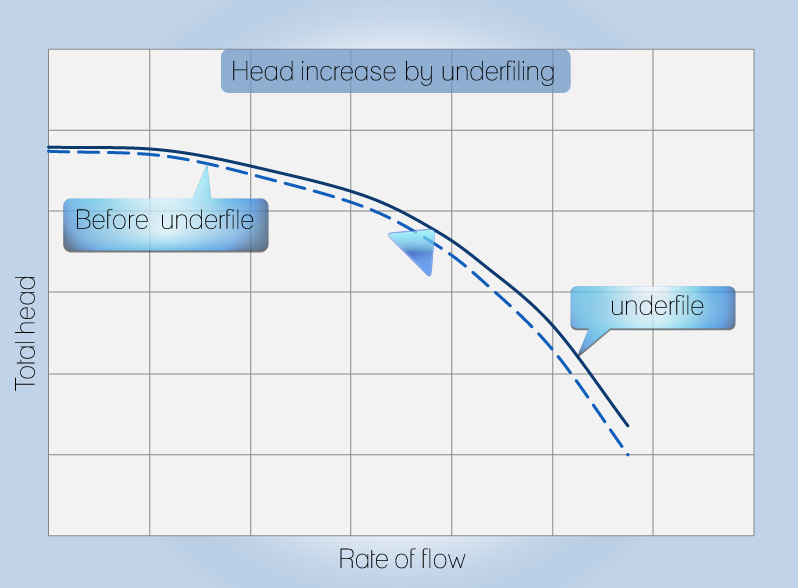

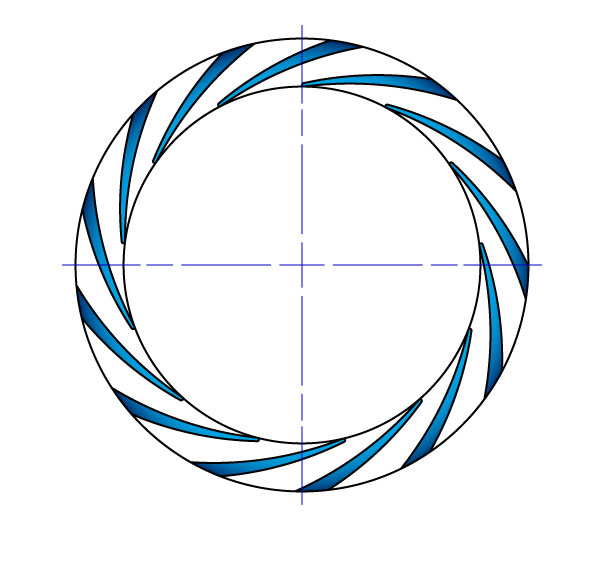

Impellers – why underfile?

Underfiling is the removal of material from the underside (also back side, “non-working” side, or suction side) of an impeller vane at the inlet or the exit. In this article, underfiling will refer to the exit. The terms “underfiling”, “back-filing”, “S2 cutting”, and “Sv cutting” are equivalent. There are probably others. A related term is […]

Diffuser versus volute

The stator section of a centrifugal pump, after flow exits the impeller, is usually either a ‘diffuser’ or a ‘volute’. The purpose of each of these two stator types is to efficiently diffuse velocity energy into pressure. Diffusers are characterized by a plurality of radially symmetric diffusing passageways surrounding the impeller. Either a volute-shaped or […]

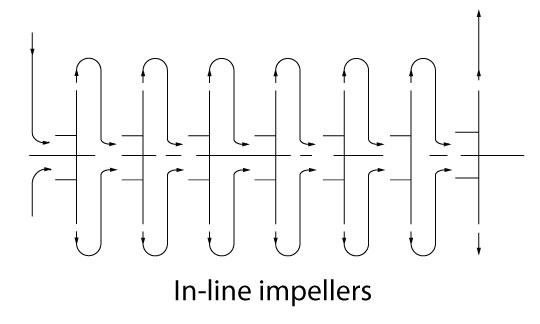

Multi-stage pump in-line (tandem) versus opposed impeller arrangements

Common to early twentieth century multi-stage rotodynamic (centrifugal) pumps were design features for minimizing axial thrust. At that time the thrust bearings available had limited load carrying capability. Design solutions evolved in two principal directions. One design approach was to hydraulically balance the thrust for each stage or for the entire series of in-line (tandem) […]