Is there any confusion about NPSH?

Randal FermanNet Positive Suction Head (NPSH) is perhaps the most misunderstood concept in pumping technology. The main source of confusion stems from multiple uses of the term in different but related contexts.

One usage of the term NPSH is to denote the suction performance characteristic of the pump itself, independent of the system into which it is installed. In this context the terms often used are ‘NPSH Required’ or ‘NPSHR’. The usual industry standard criterion for NPSHR is the value of NPSH for which a 3% reduction in pump total head occurs. The term ‘NPSH3’ is also used for this. At this NPSH condition cavitation is taking place to the point where the pump head performance is falling off measurably. NPSHR varies with rate of flow and normally increases at a steep rate of climb beyond the pump’s best efficiency rate of flow. The pump manufacturer’s NPSHR versus flow curve may include margin above NPSH3. NPSHR is normally considered the lowest value of NPSH at which the pump can be operated. It is usual practice to provide a system design margin of NPSH above the pump’s NPSHR.

The term NPSH also denotes a dynamic liquid property in a given pump intake or piping system and in that context it is often referred to as ‘NPSH Available’ or ‘NPSHA’. It is the calculated absolute total head less liquid vapor head present at the pump suction nozzle. NPSHA normally decreases as the rate of flow in the system increases. The value of NPSHA is independent of the pump.

While there are, in fact, distinct definitions for NPSHR, NPSH3 and NPSHA – and, by the way, there are other NPSH terms – the general term ‘NPSH’ is often used interchangeably to mean any one of those and the reader is left to determine from context the correct technical meaning. The main idea is to realize whether the context of NPSH is relative to the pump or to the system.

For an independent evaluation of a pump NPSH issues, contact an experienced consulting engineer who can help with your specific application. See the complete list of engineering consulting services we offer.

6 comments

[…] Is there any confusion about NPSH […]

Excellent comment Scott. Production NPSHR test results can vary significantly due to the test conditions and the individual pump configuration. Often the production test is essentially a verification that the pump NPSHR falls below a guaranteed value at one or a few flow conditions. Manufacturers will balance the necessities for publishing a competitive level of NPSHR and meeting that level on test or in the field. Manufacturers would seldom have reason to add margin for the sake of system uncertainties. Notwithstanding, the term NPSH3 is coming into more common usage and clearly represents the NPSH definition for 3% head loss. Best, Randal

Nice overview. of NPSH. Personally, I think manufacturers should not add their on margin of safety on published curves for NPSHr. NPSHr has a clear definition of 3% head loss. Safety factors should be left to the system designer or as a note at the bottom of the published curves.

Not only is the NPSH term often misunderstood but how to measure it in an existing system can be confusing. The issue often revolves around the fact that NPSH is an absolute pressure measurement. In open tank suction conditions, you have one atmosphere of pressure contributing to positive NPSHA. We so often think in gauge pressures or pressure differerential conditions that this tends to be confusing for those that do not work with pumps often.

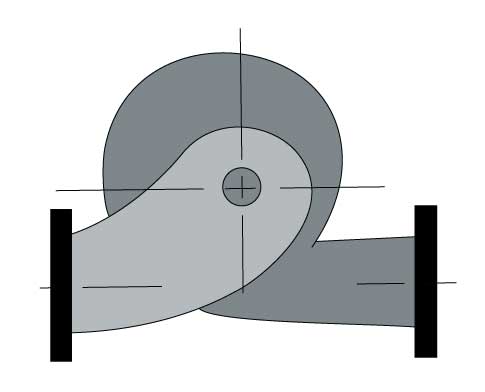

Ramy, Inducers are used mainly to lower the NPSH Required by the pump. They are found in a wide variety of applications. There are certain operational and practical limitations depending on the size, rotational speed, and other factors, so inducers are not always the best solution. As with most industrial equipment, successful application experience should count heavily toward any decision to use it. Hope this helps. Randy

please i need to know the inducer uses.