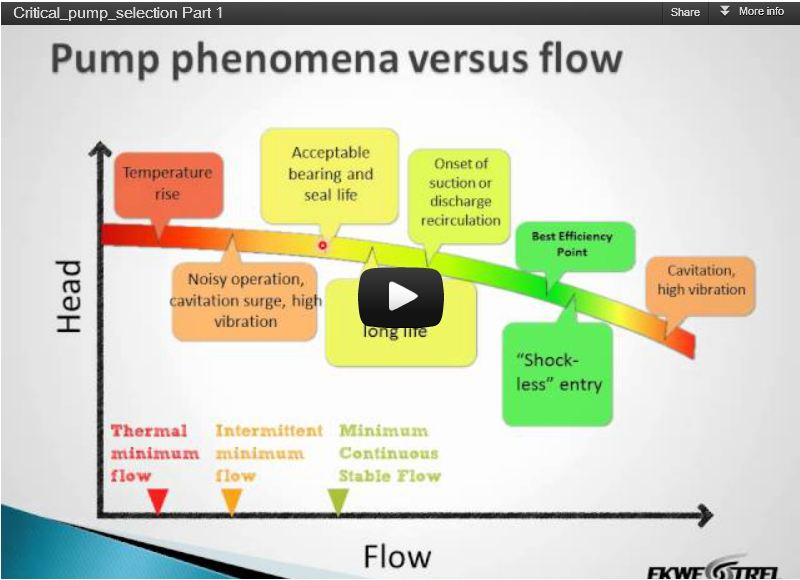

Critical Pump Selection Webinar - Video

Randal FermanAfter the success of my webinar, I am making a recording of it available for everyone who was not able to attend, and those who wanted more time to go over the material and illustrations. Thanks again to everyone who attended the live webinar! If you want to hear about future webinars, subscribe now for notifications.

4 comments

Jon,

As in many areas of engineering, there is no pat answer to this one. Suction pressure for large, high pressure boiler feed pumps, based on application experience, will typically be greater than two times the pressure needed to attain NPSHR. Some additional margin, of course, might be added. But beyond the manufacturer’s recommended NPSH margin ratio, there’s probably little, if any, benefit. On the contrary, adding pressure at the booster pump might increase the intermediate piping and valve pressure ratings and certainly places a greater demand on the main boiler feed pump’s mechanical seals, or results in higher leakage and heat loss with throttle bushing type seals.

I am certainly interested in other readers’ comments on this one.

Best,

Randal

Randal, you mention boiler feed pumps in the impeller underfiling article, and I watched your excellent video on critical pump sizing…

Would you have an article (future?)/words of wisdom to share about sizing a combination Boiler Feed Water pump with a booster pump? For example, you might describe how you would modify the flow chart in your preso… Do you typically start with getting the main pump sized (it often has ITOs), and then use it’s NPSH/head/flow “demand” to size the booster? And then iterate (grin)?

Thanks in advance.

Alexandre, Choice of pump nozzle size and piping velocity is tied to the particularities of the pump selection, the application and system considerations. Choice of optimal piping velocities can be considerably different than is indicated by the pump nozzles themselves. There is no single ‘correct’ guideline or rule of thumb on this matter. For each pump application type one can generally find industry accepted values for piping velocity. Good luck finding the specific values you’re looking for. Randal

Very good, I want to know about “speed of piping”.