Specific Speed – Does it Matter?

Randal FermanTo the pump engineer or pump manufacturer specific speed is terrifically important. To the specifying engineer or user – maybe, maybe not.

The term specific speed comes up frequently in pump literature, in technical papers and is always covered in pump text books. It is frequently heard in pump technical banter and if one doesn’t have a concept of it he can feel like he’s listening to a foreign tongue.

Specific speed is the basic pump performance parameter derived from dimensional analysis of the three essential variables of head rise and rate of flow (at pump best efficiency point), and shaft rotational frequency (speed). Specific speed is independent of pump size and serves as a primary index or type number of pump hydraulic performance.

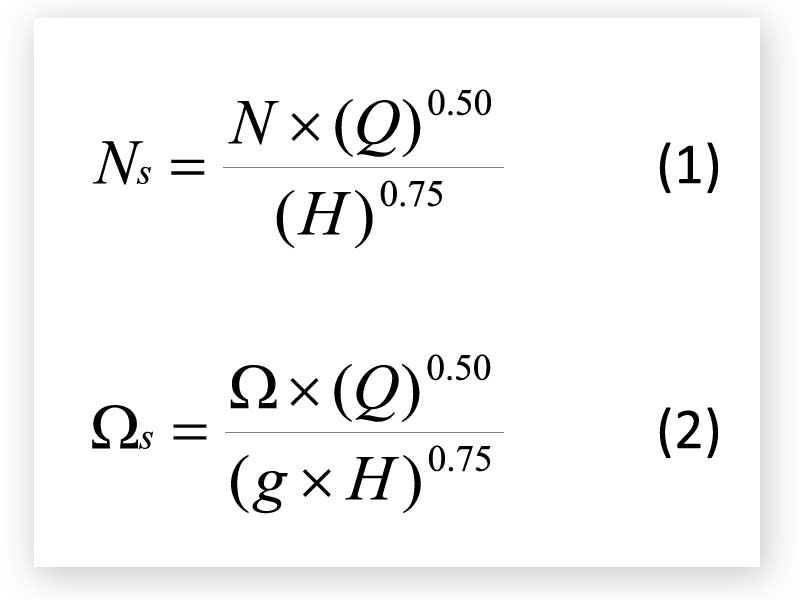

Equation (1) is the customary form of specific speed that still prevails. In the US, flow (Q) is in units of GPM, head (H) in feet, and speed (N) in RPM. The customary units for metric are varied. The units of flow (Q) can be in m3/h, m3/min or m3/s, the head (H) in meters, and speed (N) in RPM. Equation (2) is the dimensionless form of specific speed (Ωs) which depends upon homogeneous, consistent units, and will yield the same value whether the source units are USCS or metric. Ω is the shaft rotational frequency in radians per second and g is gravitation acceleration. The equation (2) form is gaining wider acceptance in technical works. One must always be vigilant about units when interpreting specific speed.

Here is a list of some important uses of the specific speed parameter. It is not a comprehensive listing, but it does cover the important ones.

Specific speed is used to:

- model or scale pump performance and hydraulic design

- estimate the effects of impeller trimming

- qualitatively or quantitatively relate pump performance to hydraulic geometry, shape and physical proportion

- optimize selection of the main hydraulic design geometry dimensions

- evaluate or optimize the attainable pump efficiency based on historical test experience

- evaluate the slope of curve to shutoff for head rise and for input power

- evaluate the potential for retrofitting and re-rating an existing pump for a new set of operating conditions

Even if these characteristics are of interest to the pump user, application of the specific speed parameter largely remains in the hands of the pump engineer. He uses specific speed all of the time – it’s usually the first parameter calculated and plays an important role in the pump selection process and in the initial design stages of modeling and parametric evaluation for a new pump.

The specifying engineer or end user does not normally get involved directly with considerations of specific speed. The pump manufacturer or equipment distributor receives the pump data sheet, and selects a pump and perhaps offers a few alternate options. At this point all decisions regarding specific speed have been made. Even if the specifying engineer or end user selects out of a catalogue, the decision will probably be based on features, performance, reputation, price or delivery, not on specific speed.

There are perhaps a few notable exceptions. For example, a pipeline engineer dealing with a large capacity transport system. He considers the pipeline hydraulic profile, the pump station spacing, the number of pumps per station, the driver and pump operating speeds and the number of pump stages. All of these tie in directly or indirectly with pump specific speed.

But generally, pump specific speed is not so important to the specifying engineer or to the end user. Perhaps its greatest value lies in knowing enough so that one can listen to a pump person speak without losing consciousness.

I am interested to hear your thoughts on this.

Randal Ferman, PE

6 comments

Is there a guideline for the selection of the most optimum specific speed for a given dynamic head ?

In other words, if a pump designer has the freedom to choose any rotational speed for his centrifugal pump, is there a guideline for the optimum specific speed for the given dynamic head requirement so that he may arrive at the best rotational speed ?

Do we have a reference curve for specific speed v/s dynamic head which could be used to check if a pump has been designed for the best specific speed at the given head or not ?